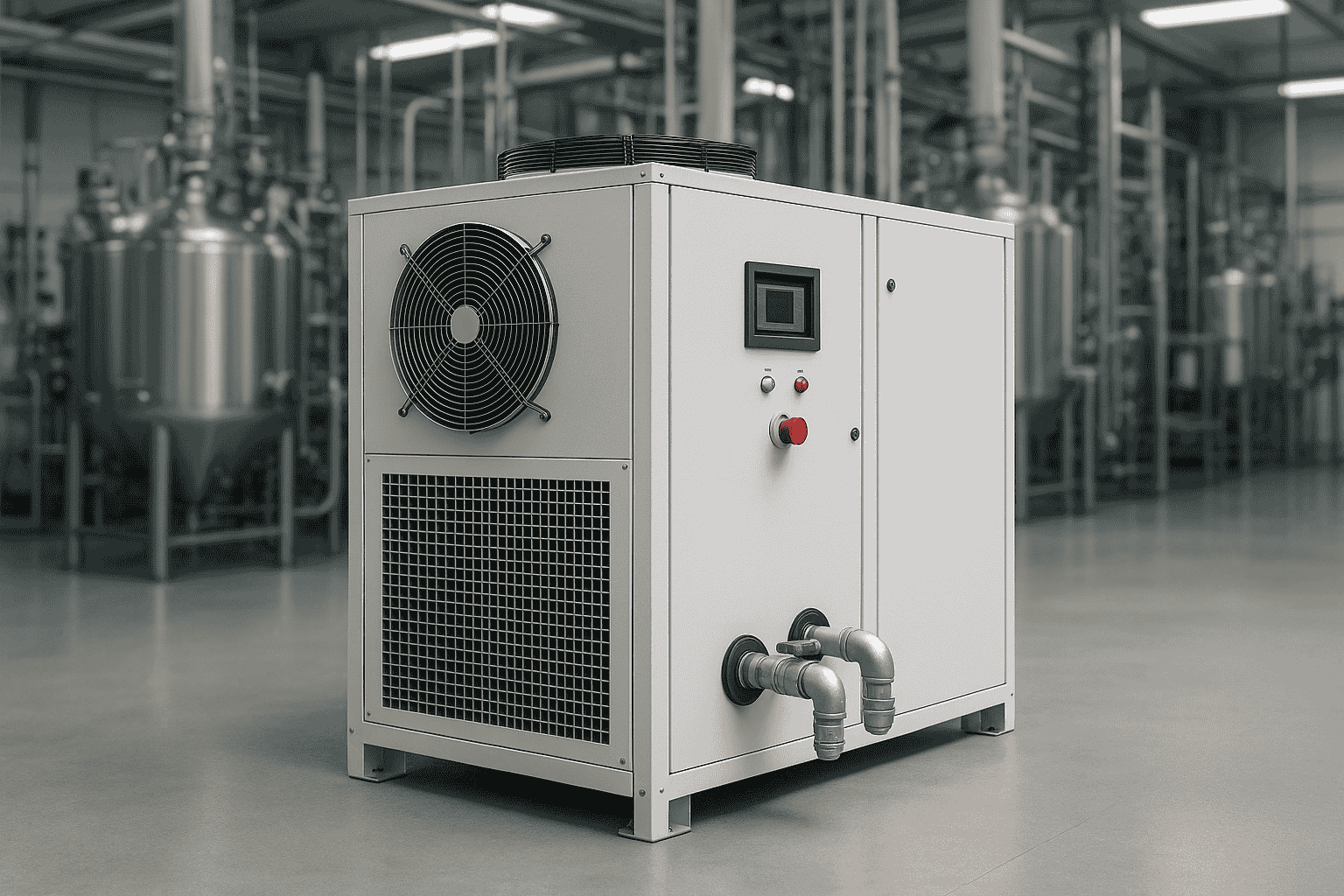

Hazardous Area Chiller – Certified Cooling Systems for Explosive & High-Risk Zones Product Description: In industries where safety is critical, such as chemical plants, oil & gas refineries, paint booths, and pharmaceutical zones, standard chillers aren't enough. You need cooling solutions that are safe, certified, and built to perform — even in explosive or flammable environments. Our Hazardous Area Chillers are specially engineered and ATEX / IECEx certified to operate in Zone 1 & Zone 2 hazardous areas, providing precise temperature control without compromising safety. These explosion-proof chillers are built with flameproof components and reinforced housing to prevent any ignition risk in volatile environments. ✅ Key Features: Explosion-Proof Components Motors, switches, relays, and enclosures are all ATEX / IECEx certified. Temperature Precision & Control Maintains process temperature within ±1°C, critical for hazardous area operations. Custom-Built for Risk Zones Designed to handle gases, vapors, and dust in Zone 1, Zone 2, Class I Div I & II areas. Stainless Steel Construction SS-304/316 grade casing ensures resistance to corrosion and chemical exposure. Remote Monitoring & Control Options PLC/HMI-based controls with optional IoT-enabled systems for real-time diagnostics. Ideal Applications: Petrochemical Plants Paint & Coating Booths Gas Processing Facilities Solvent Recovery Units Pharmaceutical Cleanrooms Oil Refineries & Storage Terminals

Send Message

About PRECITE.AI

The Best Industrial Air Cooler Chiller Manufacturers in delhi

Products

Featured ProductsWhat We Do

Have any custom requirements?

Latest Updates

Read Our Latest Updates & News

Testimonials

View All

Megha Sharma

Thanks to PRECITE.AI’s Microgreen Cold Room, we’ve scaled up production while maintaining perfect freshness. It’s compac...

Read MoreVikram Sethi

PRECITE.AI’s chiller ensures our lamination line runs smoothly without overheating. Installation was quick, and the supp...

Read MoreNitesh Jain

The 1000 Ltr Heat Pump from PRECITE.AI delivers consistent hot water for our hostel. It’s silent, low-maintenance, and c...

Read More

×

![]()